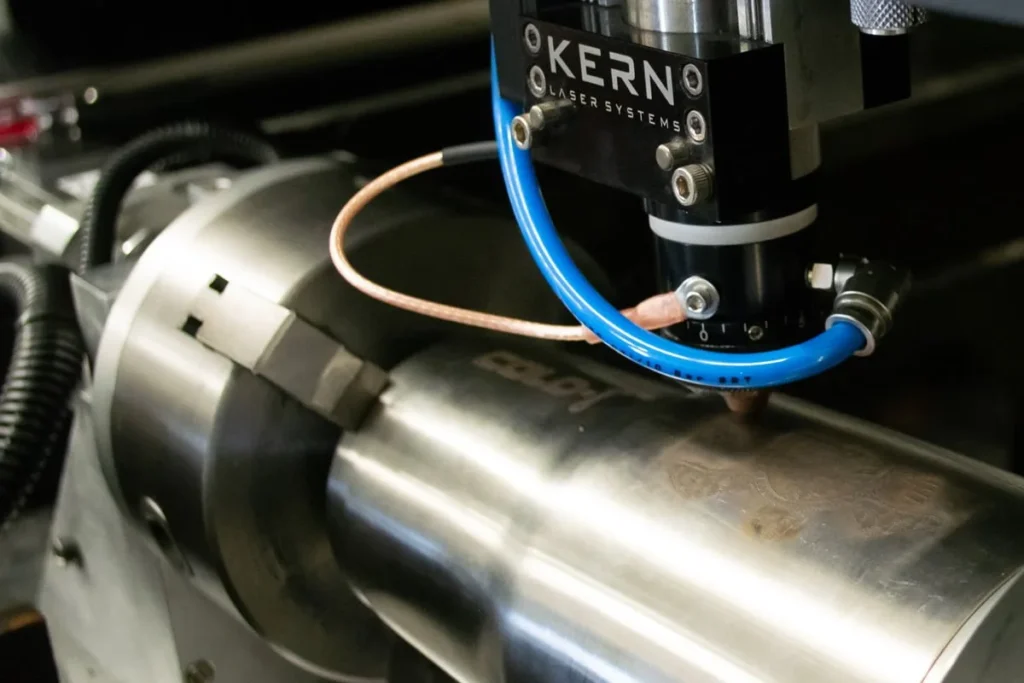

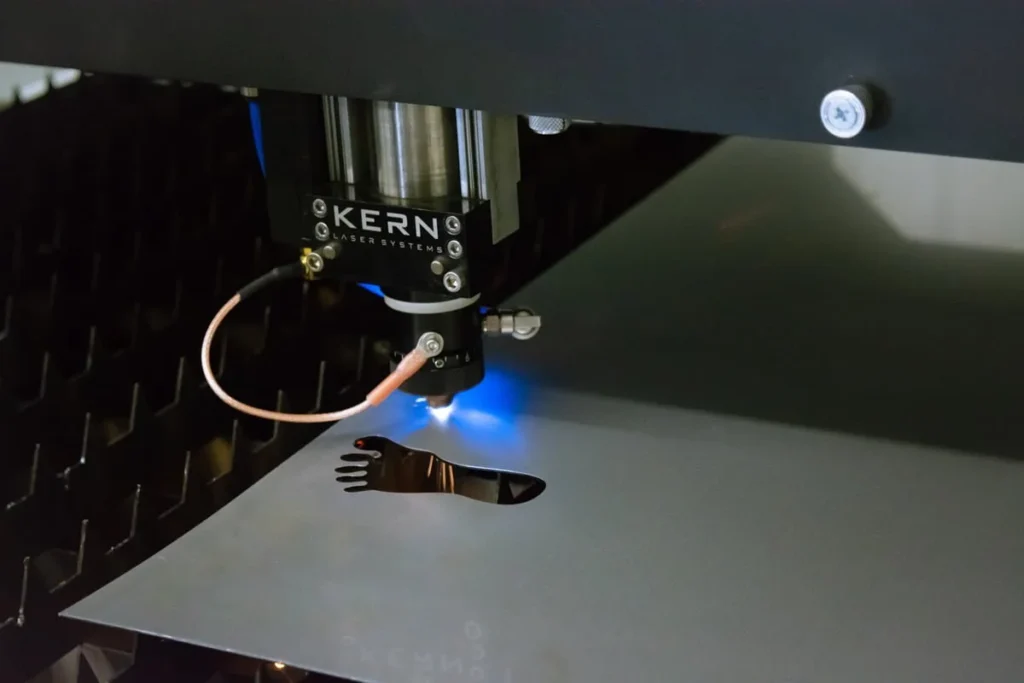

Kern’s CO2 and fiber laser systems can be equipped with innovative metal cutting technology. The metal cutting option allows for accurate cutting of stainless steel, leaving a clean, dross free edge. Stainless steel up to .090″ can be processed with Kern’s largest 650W CO2 laser. For thicker applications, Kern’s FiberCELL is best utilized with cutting capabilities of up to 1/4″ utilizing a 3kW laser.

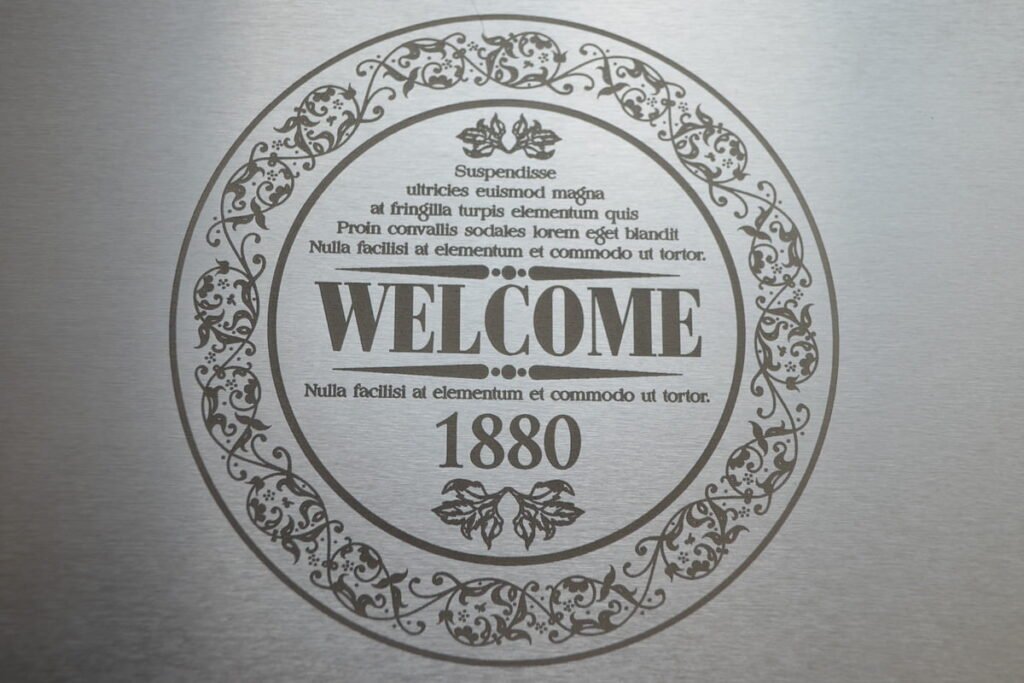

Kern’s CO2 laser systems are able to etch directly onto the metal surface or leave a durable mark with the assistance of a marking spray such as Cermark.

COMMON USES

ALUMINUM

Laser cutting aluminum requires a powerful and precise approach, and typically, a 300W CO2 laser is considered the minimum power level sold for effectively cutting this metal. However, a majority of our aluminum processing customers are running 500W or greater lasers.

Many aluminum nameplate manufacturers are running 500W laser systems to cut thin gauge aluminum tags and labels with great success. CO2 lasers are generally more effective than fiber lasers for cutting aluminum labels with an adhesive backing because of their longer wavelength, which is less absorbed by the metal and more effectively interacts with the adhesive layer. This allows the CO2 laser to cleanly cut through both the aluminum and the adhesive without excessive damage to the material. Moreover, the CO2 laser’s beam quality and precise control enable it to delicately handle the layered structure of these labels, ensuring a cleaner edge and reduced risk of burning or warping the aluminum or adhesive.

Fiber lasers are also a great solution for cutting aluminum due to their shorter wavelength, which allows for a more focused and intense beam, leading to cleaner and more precise cuts. Lasers from 1kW to 3kW are available on the FiberCELL platform.

Marking aluminum with a Kern laser system is also possible. A laser marking spray is used to leave a dark, durable mark on the surface of the metal. Cermark and Thermark are two laser marking sprays used on metal.

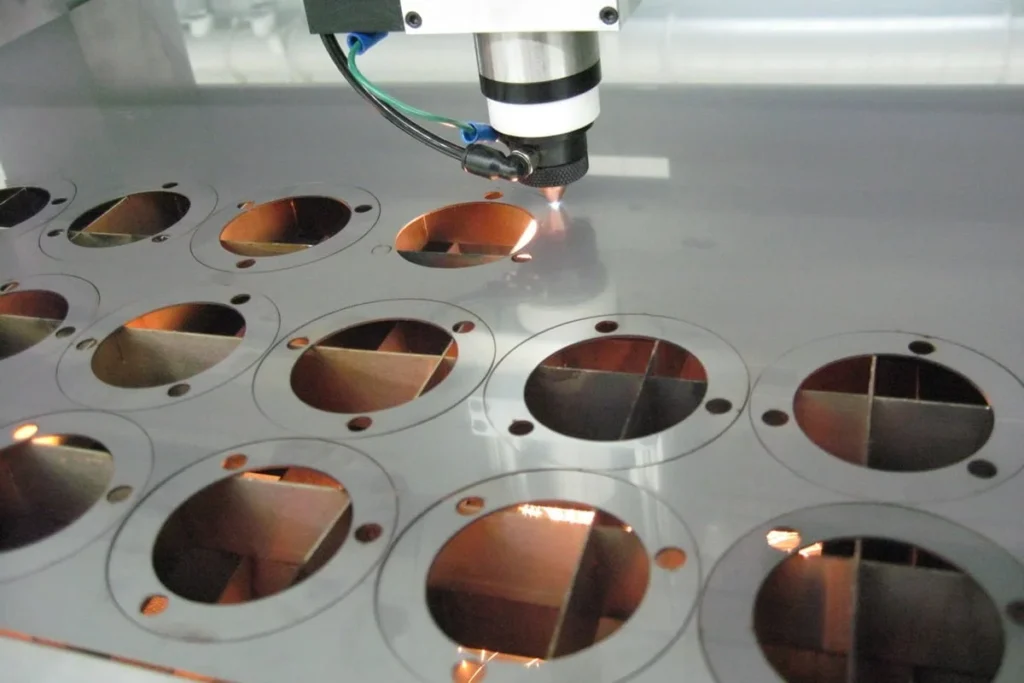

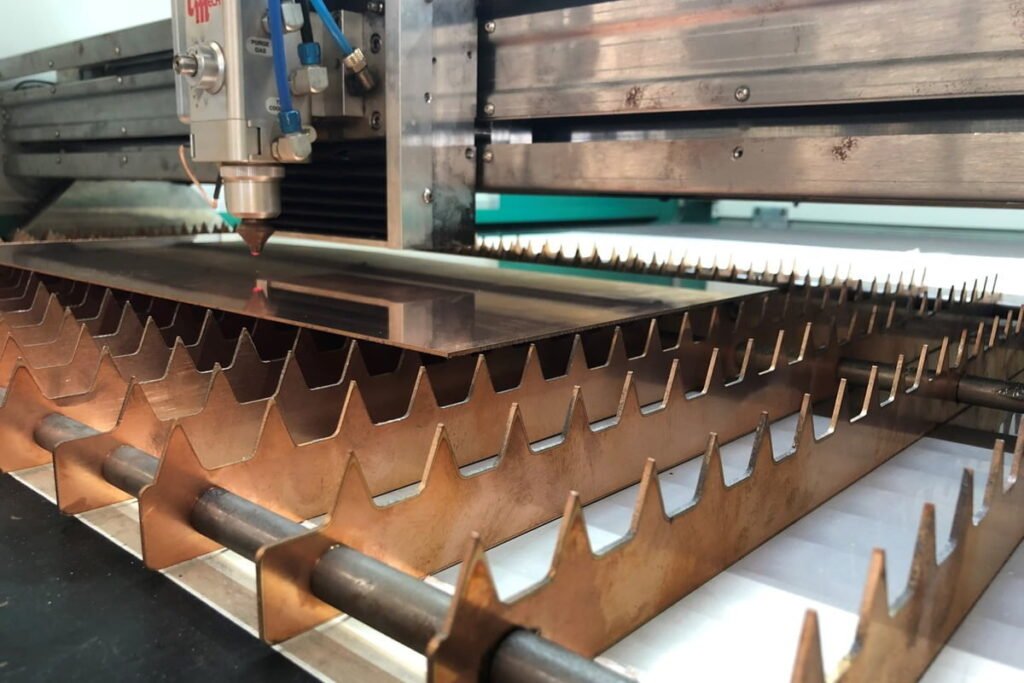

COPPER

Fiber lasers are highly effective at cutting copper due to their shorter wavelength, which is more readily absorbed by the reflective surface of copper, allowing for efficient and precise cutting. Their high intensity and focused beam enable cleaner cuts with minimal kerf width, making them ideal for intricate designs and fine details in copper work. Additionally, fiber lasers offer better energy efficiency and faster cutting speeds compared to other laser types when working with conductive materials like copper.

COMMON USES

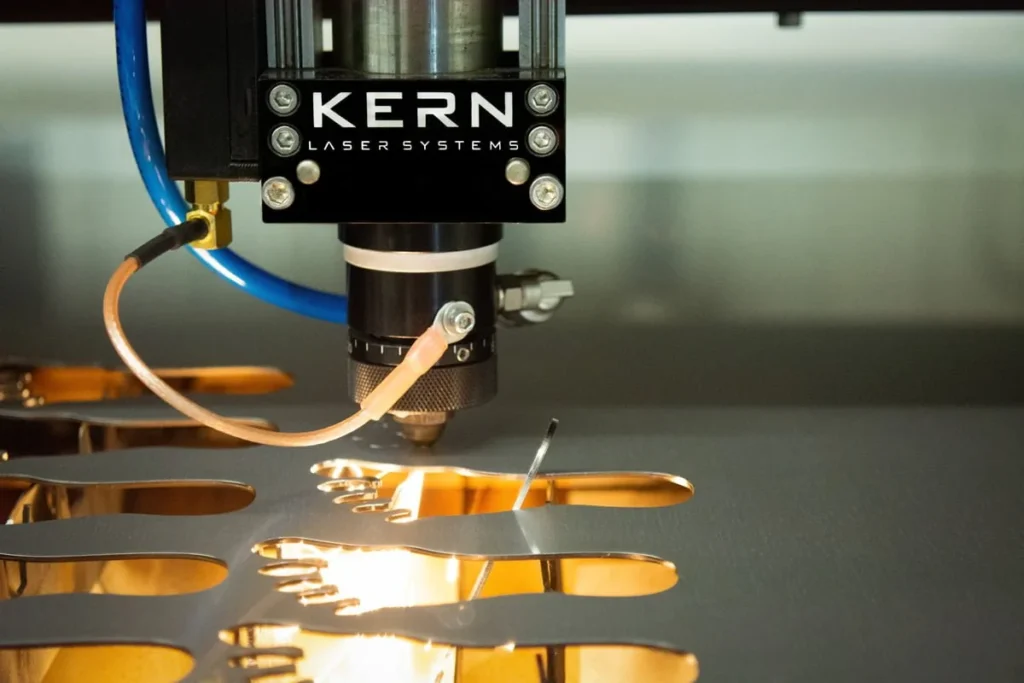

BRASS

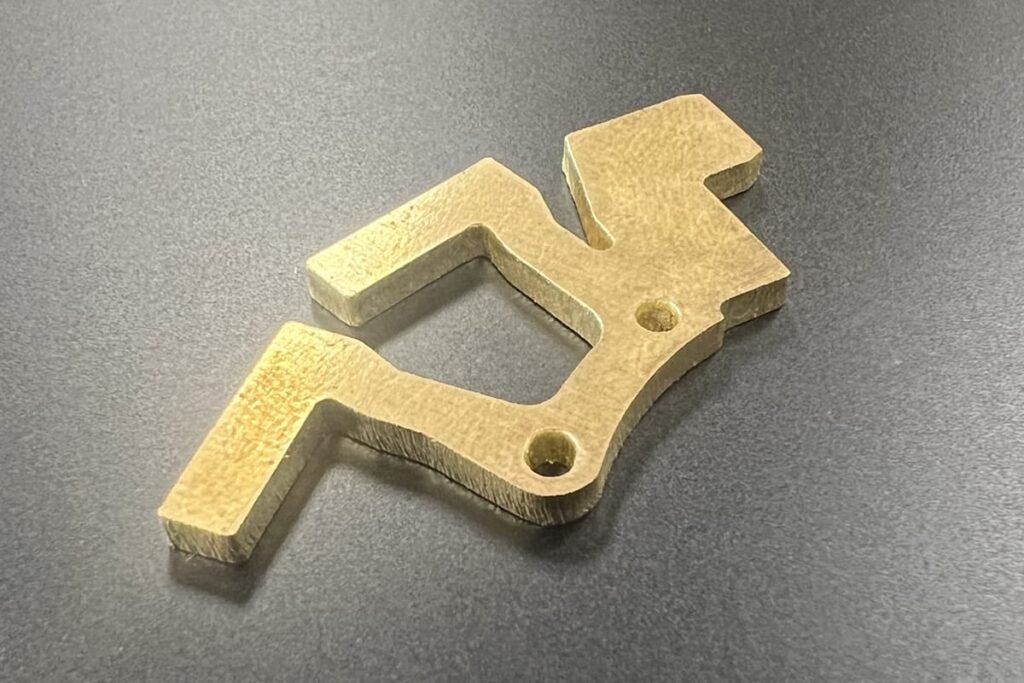

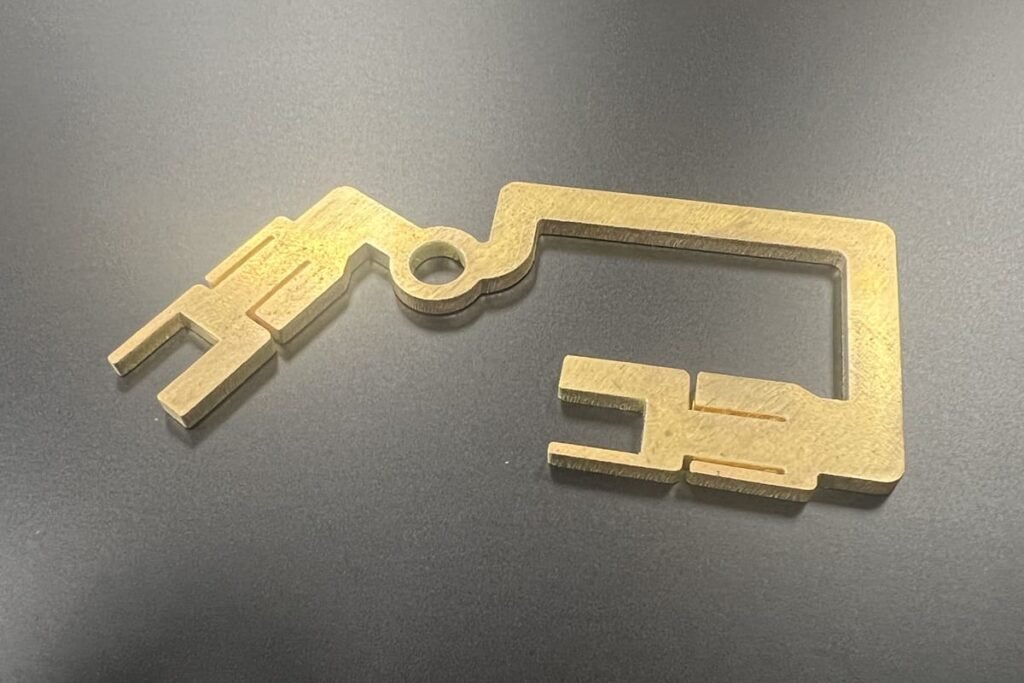

Brass is an alloy consisting of zinc and copper. Laser cutting brass with a CO2 laser often requires careful power and speed adjustments due to brass’s reflective nature, which can pose a challenge to this laser type. On the other hand, a fiber laser, with its high intensity and shorter wavelength, is more efficient and precise for cutting brass, making it a preferable choice for intricate designs. Laser systems are capable of cutting sheets of brass to a high yield, reducing material waste and providing optimal sheet usage. Laser-processing brass results in clean cutting with an air assist, which greatly reduces or eliminates dross.

CO2 lasers below 500 watts have a difficult time cutting this reflective metal. Kern’s 500 and 650 watt metal cutting system can cut most brass alloys up to .040″ and .048″, respectively. The FiberCELL 3kW system can cut up to .1875″ brass.

COMMON USES

TITANIUM

Titanium has a low density and is a strong lustrous, corrosion-resistant metal. This “space age metal” is used in a variety of industries and is cut with these machines. A dark, consistent etch can be applied to the surface of this metal by using a marking spray or oxygen assist gas.

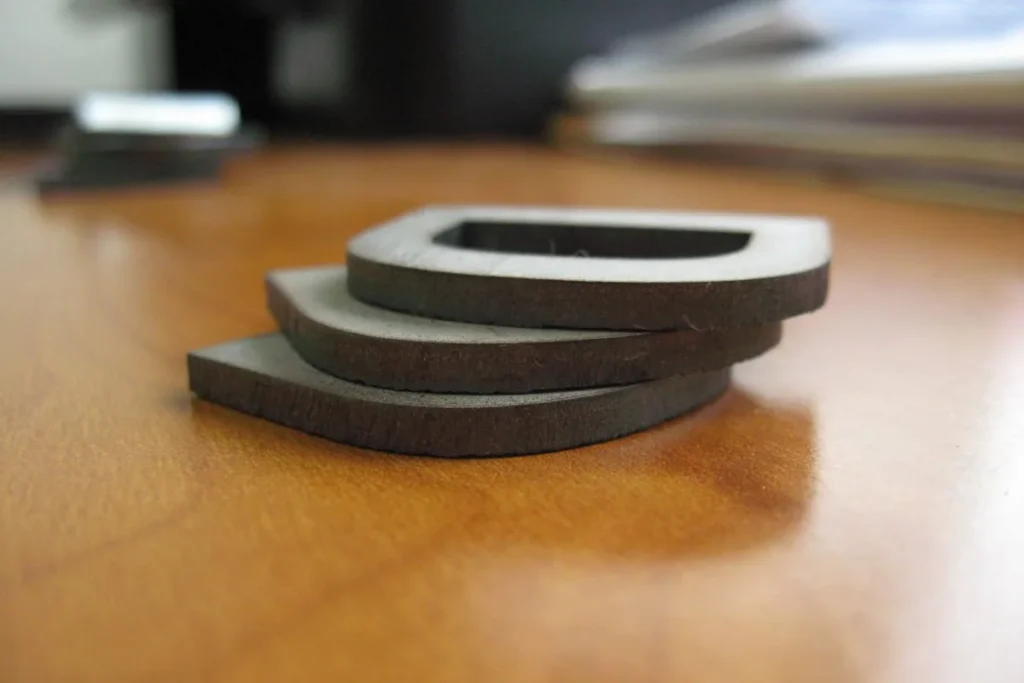

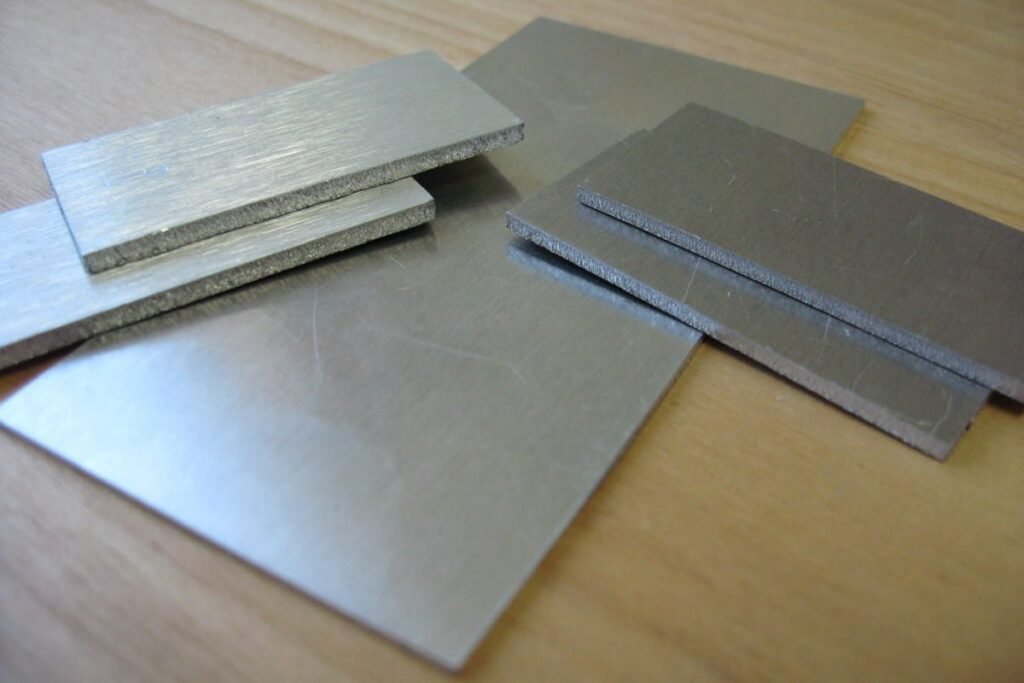

We offer in-house guillotining to your required size and can subcontract slitting services. Custom shims are available for all products in our range, including brass, steel, and stainless steel shims. No job is too small or too large!

For custom shim enquiries, call us at 02 4646 1166 or email your drawing to sales@ppshim.com.au for expert advice and fast service.

1. Contact

Let us know your requirements, and our team will assist you.

2. Quote

We’ll provide pricing based on your specifications.

3. Delivery

Have your order delivered or collect it from our head office.

Custom Shim FAQs

Which industries commonly utilise custom shims?

Custom shims play a vital role in various industries, offering precise solutions for alignment, spacing, and load distribution.

Construction: Assists in structural alignment and load balancing for stability.

Automotive: Ensures precise alignment and spacing in vehicles and components.

Aerospace: Provides critical load distribution and precision in high-performance systems.

Engineering: Supports machinery with accurate alignment and gap adjustments.

What types of materials are suitable for custom shims?

Custom shims can be made from materials like stainless steel, brass, copper, and plastic, selected based on factors like durability, flexibility, and environmental resistance.

What finishes are available for custom shims?

Custom shims can undergo various surface treatments, such as electroplating for corrosion resistance or polishing for a smooth finish, tailored to enhance durability and functionality.

Are custom shims available in different thicknesses?

Yes, custom shims are available in a wide range of thicknesses, from thin, flexible options for fine adjustments to thicker, more rigid ones for heavy-duty applications. Contact our expert team for specific thickness requirements.

Is it possible to request custom shapes or sizes for shims?

Yes, custom shims can be requested in any shape or size. Using advanced cutting technologies like laser and water jet cutting, we ensure precise, tailored solutions for your project. Contact us on 02 4646 1166 for your specific requirements.